HUNAN KINGCERA ENGINEERING CO.,LTD

- Address:NO.18,East Twelve Road,Changsha Economic and Technological Development Zone,China

- Postcode:410100

- Fax:+86-731-84069186

- E-mail:info@kingcera.com

- Website:http://es.kingcera.com

- Sales office

- Tel:+86-731-84019856

- Fax:+86-731-84069186

- E-mail:sales@kingcera.com

- Service office

- Tel:+86-731-84067818

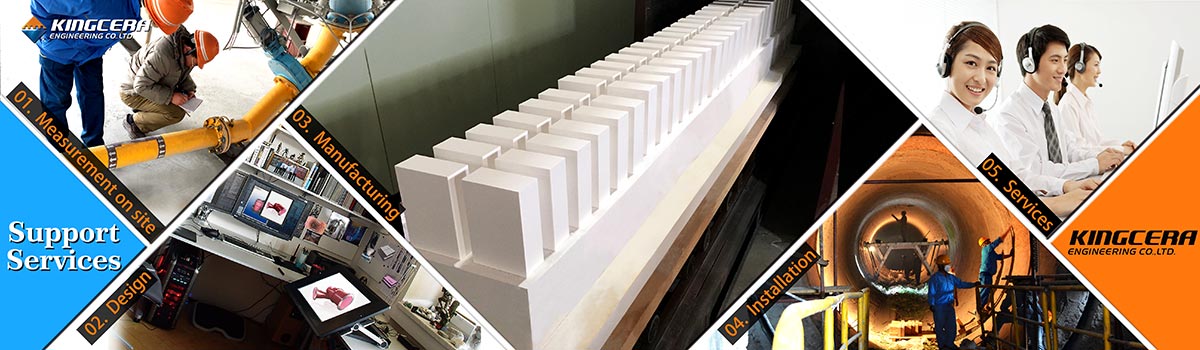

【CASE STUDY】Ceramic wear liners - Transfer Station Insert Chute

Time:2021-03-01 Reader:

Material Handled: Iron Ore

Plant Location: Western Australia

Tonnage: 12,000 tonnes per hour

Particle size: 30-50mm

Drop height: 3 metres

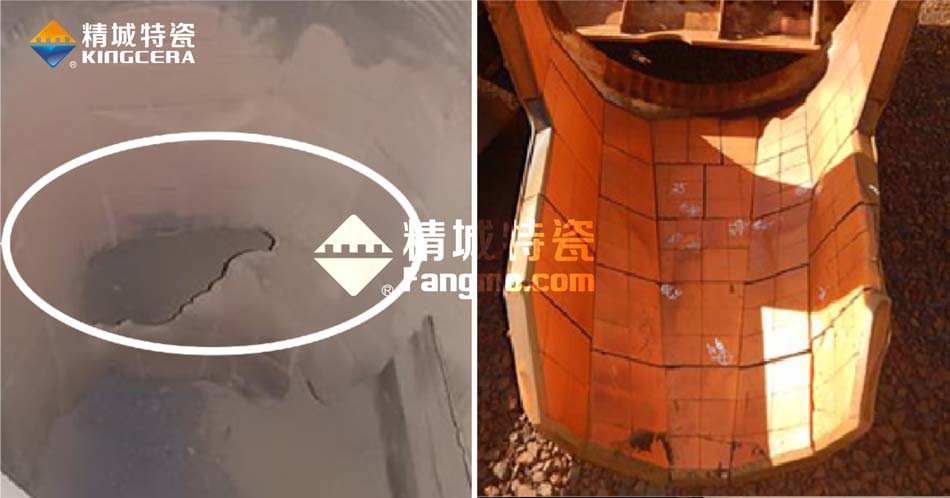

A Australian Iron Ore mine was experiencing high costs from the lack of wear life for transfer chute, the previous lining system consisted of 50mm thick 92% Alumina ceramic tiles installed as 63mm thick composite ceramic wear liner.

The image show the state of the liners were holed after only 7 weeks after installation The wear of some liners is so severe that the steel backing plate had worn through and into the parent metal of the equipment. This means the material has direct contact with the chute and therefore has the possibility to directly generate a stoppage to repair the equipment.

Solution

In close consultation with the client, Kingcera designed and manufactured custom ZTA liners to exceed the requirement of the customer, 50mm thick ZTA ceramic tiles installed as 63mm thick composite ceramic wear plates.

Results

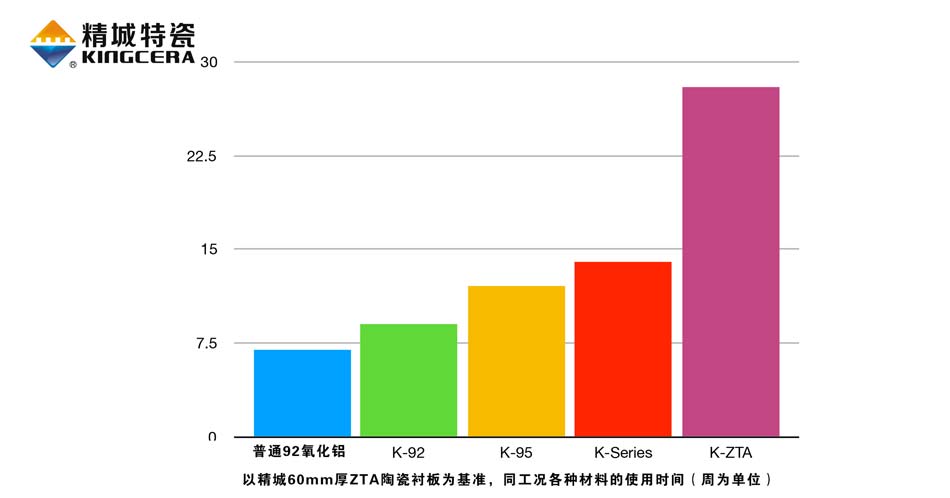

Inspected after 24 weeks in service showed a maximum wear of 32mm, with 18mm of ceramic material remaining. By employing 63mm thick ZTA ceramic wear plates, the customer is forecasting for a 28 weeks service life to be readily achievable, a significantly increased service life and associated cost saving compared to the original 7 weeks obtained.

Conclusion

In relation to the cost per processed ton, Kingcera ZTA wear liners were over 4 times more cost-effective than previous wear liners. The success of the ceramic wear liners allowed for consistent performance without the need for costly maintenance. The system eliminated human exposure to the equipment for the duration of service and therefore increased safety.

63mm ceramic wear liners Service time for the chute in iron ore mining(weeks)